Valves From IPS

At IPS we can offer various types of valves.........

VALVES TYPE & FUNCTION

Gate Valves

Actuated Valves

Ball Valves

Throttling Valves

Butterfly Valves

Non Return Valves

Diaphragm Valves

Strainers

Pressure Valves

ON – OFF SERVICE

Gate Valve

Gate valves have one major advantage over ball valves. Because the opening and closing mechanism is slow, they can't cause a water hammer

Valterra SLIDE KNIFE GATE FOR LOW PRESSURE APPLICATIONS

One of the largest gate valves in the world DN2800 (108 IN)

ACTUATED VALVES ELECTRIC/PNEUMATIC

lPneumatic (fast opening and closing)

Fail safe open, fail safe closed , double acting,

switchbox, solenoid valve , positioner

lElectric (slow opening and closing)

Various voltages, extra limit switches, fail safe

option , 4-20Ma positoner

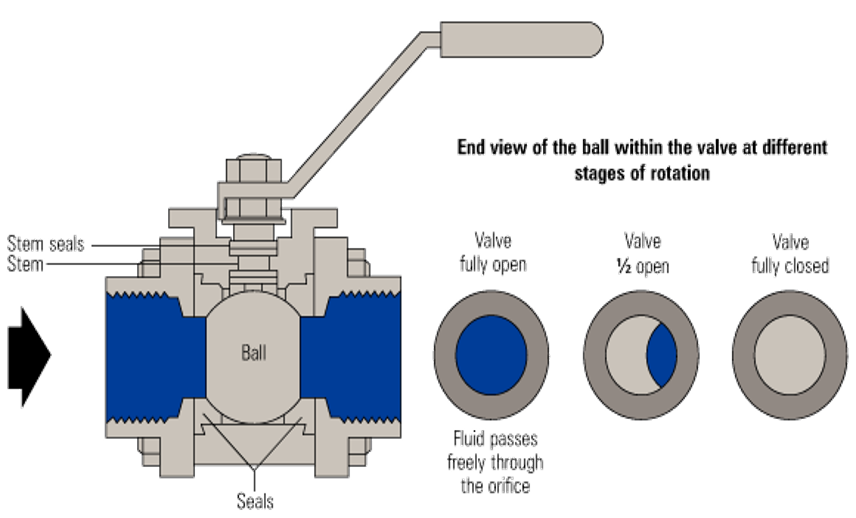

Ball Valve (on-off)

Ball Valve Quarter-Turn

Ball valves have several advantages. They are easy to turn on and off quickly,. They allow the user to tell at a glance if the valve is open or not. They are durable, rarely freeze even with years of use, provide reliable service, and are extremely versatile. Ball valves are used in home plumbing, industrial applications, oil and gas applications, marine applications, pharmaceuticals, and many other fields.

The primary disadvantage of the ball valve is the requirement of space. In tight applications, you may not have 90 degrees to turn the valve's handle. Also, in rare instances a ball valve can create a water hammer condition

THROTTLING

(Regulating) SERVICE

Globe Valve

A globe valve, different from ball valve, is a type of valve used for regulating flow in a pipeline, consisting of a movable disk-type element and a stationary ring seat in a generally spherical body.

Needle Valves provide proportional opening to needle travel

for more accurate metering applications and other fine

adjustment flow control applications

Butterfly Valve

A butterfly valve is a quarter-turn valve used to regulate flow. The disc in the body of the valve is positioned perpendicular to the flow in the closed position, and rotated one quarter of a turn to be parallel to the flow in the fully opened position. Intermediate rotations allow regulation of liquid flow

Lugged butterfly valves have threaded inserts at both sides of the valve body, enabling them to be installed in a system using two sets of bolts and no nuts. The valve is installed between two flanges using a separate set of bolts for each flange. This allows either side of the piping system to be disconnected, without disturbing the other side.

Lugged butterfly valves used in dead end service generally have a reduced pressure rating. A lugged butterfly valve mounted between two flanges will have a 150 psi pressure rating. Whereas, the same valve mounted with one flange will have a 75 psi rating in dead end service.

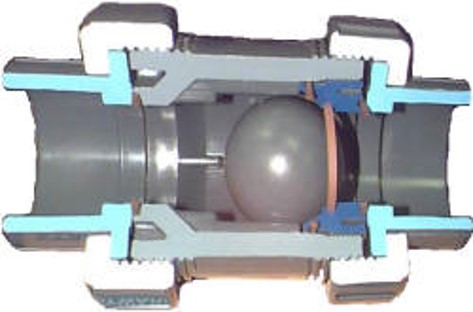

Prevention of back flow

Non Return valves

Non return valves allow the fluid to flow only in one desired direction. Any flow in the opposite direction is mechanically restricted from occurring. A non-return valve is fitted to ensure that a medium flows through a pipe in the right direction, where pressure conditions may otherwise cause reversed flow. Non return valves are used to prevent back flow of fluid, which could damage equipment or upset the process.

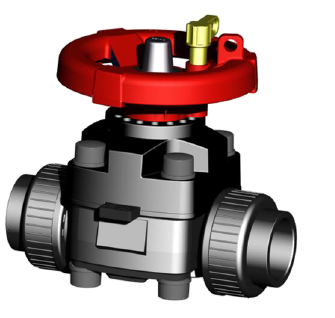

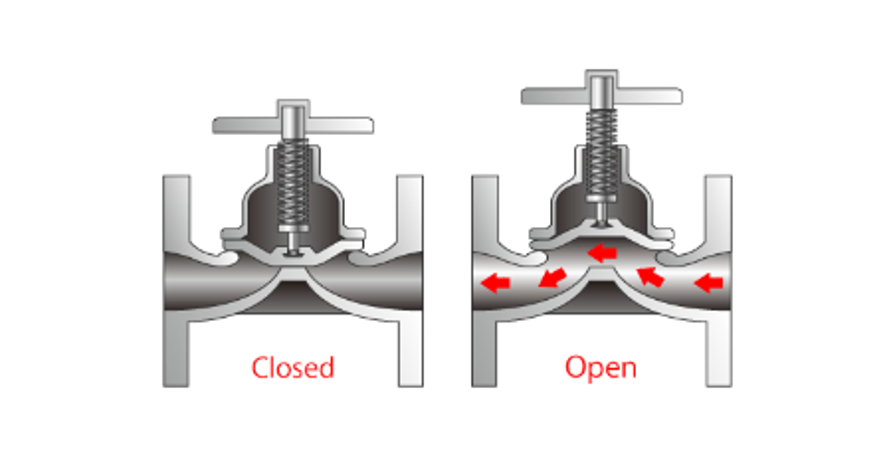

DIAPHRAGM VALVES

Diaphragm valves (or membrane valves) consists of a valve body with two or more ports, a diaphragm, and a "weir or saddle" or seat upon which the diaphragm closes the valve. The valve body may be constructed from Plastic or Metal

The weir-type design is the most popular type of diaphragm valve and it is best for general use applications or for tough corrosive and abrasive services. They are best used to control small flows. The body of the weir-type has a raised lip that the diaphragm comes into contact with. Weir-type valves use a smaller diaphragm because the material does not have to stretch as far. The material can be heavier so the valve can be used for high-pressure and vacuum services.

Strainers

Y-Strainers are devices for mechanically removing unwanted solids from liquid, gas or steam lines by means of a perforated or wire mesh straining element. They are used in pipelines to protect pumps, meters, control valves, steam traps, regulators and other process equipment.

Pressure valves

The ASV Stubbe 712R Pressure/Relief Valve has two functions. As a Back Pressure sustaining Valve, installed in-line downstream of a pump, the back pressure below the metering pump is maintained. When installed in the branch of a tee it is a Pressure Relief Valve.

The stubbe 755 /765 reducing valves is designed to reduce primary upstream pressure to a constant downstream working pressure

If you have a valve enquiry contact sales@ipsflowsystems.com