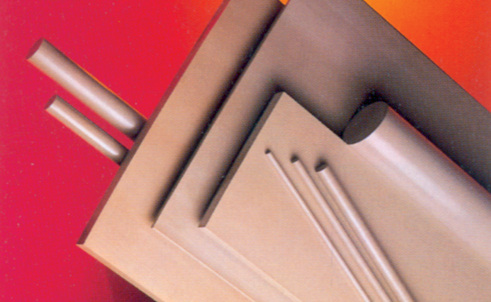

Sheet and Rod

"Plastic semi-finished materials can be fabricated very easily"

Using heat forming, bending and welding techniques plastic sheet materials can be used to construct a huge range of fabricated items - from tanks to fume scrubbers.

In a similar way, conventional machining methods such as cutting, boring, drilling, toming and threading can be used to produce an endless variety of finished parts and subcomponents.

Fabricated or machined parts can then be incorporated into large assemblies or other plastic systems, providing material consistency and improving the integrity of the system.

Our range of sheet, rod and machining shapes includes all common thermoplastics as well as the most advanced technical materials for the most demanding applications.

PVC-U Excellent chemical resistance and dielectric properties, good tensile, flexural and mechanical strength, low moisture absorption, excellent dimensional stability and good flammability characteristics. Maximum temperature +60°C.

Corzan PVC-C Excellent chemical resistance, good mechanical strength and rigidity, high heat resistance, excellent flammability properties (self-extinguishing), low thermal conductivity and good abrasion resistance. Maximum temperature +100°C.

Polyethylene Tough, excellent chemical resistance and electrical properties, low coefficient of friction, light-weight, very low moisture absorption, excellent flexibility and good strength in cold environments.

Polypropylene Has excellent chemical resistance, high heat resistance and good mechanical strength. Light-weight, good insulating properties, excellent dielectric strength but poor UV resistance and low impact strength at freezing temperatures. Maximum temperature +100°C.

PVDF Outstanding mechanical, physical and chemical properties, very wide operating temperature range, high impact strength and thermal stability, excellent abrasion resistance, self-extinguishing. Maximum temperature +140°C.

Our Partners in Sheet and Rod

Agru

As a reliable, professional supplier, AGRU offers everything from semi-finished products through to technologically optimised injection moulded fittings, all from a single source. Founded back in 1948 by Alois Gruber senior in Austria, nowadays the company is one of the world’s most important single-source suppliers for high-quality piping systems, semi-finished products, concrete protection liners and lining systems made from engineering plastics. With its expertise in producing engineering plastics components and developing tailored solutions, AGRU is present in virtually every sector of industry. Application areas include water and gas infrastructure, the energy sector, chemical and heavy industries, semiconductor and life-sciences, tank and apparatus building, naval and aviation industries, civil engineering and mining, and building construction. The possibilities opened up by Agru are manifold, just as the requirements of the worldwide customers are diverse.